This post has been republished via RSS; it originally appeared at: New blog articles in Microsoft Tech Community.

Industry challenges

The new challenges for Industrial organizations can be categorized into three types: making decisions in an increasingly complex & uncertain environment, balancing contradictory constraints (revenue, cost, efficiency, resiliency, carbon footprint…), reacting quickly, and adapting with agility to real-world changes.

They must, for example, balance the usual flow of suppliers, raw materials, and specialized processes with unforeseen shifts in consumer demand. Often, however, they lack the visibility and understanding of the impact their decisions or external changes will have on their organization.

From detection of problems to simulating real-world scenarios

To overcome those challenges, industries have first turned to sensors, with IoT investments to monitor the present, providing awareness and detection of problems on physical assets. This helped them to better react to situations in real-time. They then made predictions from historical data, extending capabilities for failure prediction and predictive maintenance. Digital Twins, with new system modeling and connectivity capabilities, help industries connect to the ecosystem, based on physical asset data, enterprise data (IT/OT), and contextual data. They were thus able to augment their awareness on a larger scope.

There is now a huge opportunity for enterprises to get full visibility on all possible futures of the organization, considering cascading effects and unexpected events, in the context of the connected ecosystem. This is the next logical and critical step, being able to test and optimize any scenario and automating this process.

Simulation Digital Twin can be applied to a wide category of use cases. For example, Michelin uses it to optimize strategic sourcing to optimize its global profit margin by 5%, and Nexans harnesses Cosmo Tech technology to support its E3 performance goals to become carbon neutral in 2030.

The challenges in implementing the Simulation Digital Twin

While contextual awareness, performance predictions, and prescriptions can deliver huge ROI, it requires going beyond the capability to scale digital twin and analytics models to hundreds or thousands of independent assets. The capability to scale those in the context of an enterprise business and its ecosystem is an important factor to deliver real value. Delivering these new capabilities requires solving a number of technical challenges.

|

Challenges |

Key required services for Digital Twin Platform |

|

Creating a digital dynamic replica of a complex real-world for past, present, and future states |

In-sync, ecosystem modeling and simulation of entities, their interactions, and dynamics to monitor, anticipate, and automatically mitigate the impact of disruption. |

|

Testing virtually, in a transparent and auditable way |

SimuOPS workflow management for an in-sync baseline, offline cloning of archives, what-if parameters, and synthetic outputs. |

|

Combining different types of simulation and analytics |

Hybrid AI orchestration: containers for connected engines computing at scale, experiments library for optimization, Monte Carlo, sensitivity analysis, parameter inference. Synthetic data-based Data science & Machine learning playground. |

Architecture to continuously predict and automate in real-time at scale

Simulating any real-world scenario requires

- modeling and simulation components, including their interactions and behavior

- predicting the consequence of events and the propagation of uncertainty

- performing virtual testing on any parameter.

In addition, deploying autonomous systems requires training ML Models used for automation to be robust to uncertainty when data are not observed, to ensure automation is safe and reliable.

Over time, Simulation and Digital Twins services should also be available at the Edge for:

- providing awareness at the Edge, through virtual sensoring on anything, whether on physical asset data or business data, such as stock levels

- making the edge truly functional, to perform testing on autonomous systems

Cosmo Tech, provides robust and scalable modeling, simulation, and cloud orchestration platform. The Simulation Digital Twin platform complements Microsoft Azure Digital Twins and IoT platforms to provide comprehensive 360° Simulation capabilities.

360° Simulation capabilities

- enable full visibility on all possible futures

- consider cascading effects and unexpected events across the ecosystem.

Cloud-Native simulation orchestration can

- Easily scale simulation in the cloud

- Provide native access to Cloud services

- Assemble and run Hybrid AI experiments

- Support integration of 3rd party Simulation technology

Cosmotech simulation platform architecture

Simulation Digital Twins insights may be consumed at a large scale in the enterprise, targeting a wide range of users through different interfaces, such as

- Existing business applications (ERP, EAM…), augmented with new scenario and predictions capabilities

- AR/VR to train and support operators on the field

- Automated system trained by synthetic data

- dedicated application to support business experts to optimize decision-making, providing integrated scenario hierarchy management, simulation control, and visualization as well as scenario comparison (scorecard, detailed analysis).

- 360 Modeling and Simulation

Scaling Digital Twin simulation requires being able to model large-scale systems. A typical example of scale required for one scenario run for one of our customers in the energy sector is as follows:

|

Number of Twins |

Number of Twin relationships |

Synthetic Data size |

Synthetic Data entries |

|

1,000,000 |

3,500,000 |

100 GB |

30,000,000 |

To support Modeling at scale, in terms of twin complexity, our Complex System Modeling Language (CoSML) helps modelers map the real-world systems and their myriad of interconnections and relationships as they are. CoSML is a proprietary modeling language that allows the modeling of all types of industrial, social, and natural systems. It is an object-oriented modeling language and is primarily composed of building blocks, hierarchies, interactions, and dynamics.

Leveraging CosML, the Simulation Studio is a model-driven and user-friendly tool designed for developers and modelers who are experts in business and operational systems modeling and developing digital twins. The Studio will automatically generate executable simulation engines as well as model ontologies in Digital Twins Definition Language (DTDL), a standard Modeling language that is part of the open-source initiative of the Digital Twin Consortium.

In addition, Comets is a Python library for experimenting with numerical models and simulators.

- Azure Digital Twins as Data source

Cosmo Tech is using Azure Digital Twins, also compatible with DTDL-based ontologies to provide a consistent end-to-end modeling experience and to export ontologies to data sources. Azure Digital Twins is also hosting an in-sync representation of Digital Twin data acting as a single source of truth for simulation initialization.

Industrial DataOPS solutions such as Cognite Data Fusion (CDF) can provide data contextualization with the ecosystem, and directly connect to Azure Digital Twins.

- Data Gateway Sync

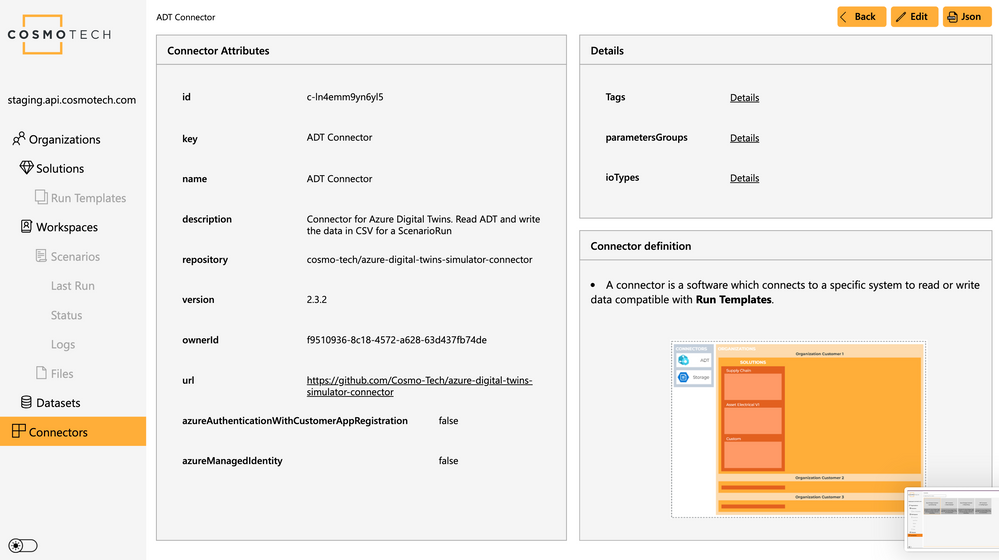

The Cosmo Tech Platform provides several types of connectors allowing the management of simulation input and synthetic output data.

- SimuOps

The SimuOps service simplifies the management of simulation models and data lifecycles. It provides a comprehensive framework for developers and data scientists to accelerate the development of digital twin applications based on data from the past, present, and future; through a single datastore, with consistent ontologies.

- Hybrid AI Orchestration

The Hybrid AI orchestration service provides full flexibility to describe composable workflows of simulation and AI-based experiment computing, independently of the simulation engine vendor and technology.

- Organisation Management

The Organization management service is managing how information is organized in the platform and how they interact together to provide a full enterprise-grade experience.

The administration console helps IT users to manage the platform by providing quick access to all platform configurations (organization, dataset, scenario, run workflow, connectors).

- Synthetic Data Storage

Synthetic data storage service is used to process live data as well as store simulation output time series and input snapshots for offline analysis.

- stream/real-time for immediate insights through Azure Event Hub

- data warehouse for full reporting, based on Azure Data explorer

- Twin update for virtual sensor and business apps with Azure Digital Twins

- Application Analytics

Application analytics services can be used to create

- AI/ML with Azure ML and Azure Synapse Analytics

- RL model training on Synthetic Data with Project Bonsai

- Edge for automation

- Low code apps for business users with Power Apps

- Connected Platform Services

- Security with Azure Defender

- Authentication with Azure Active Directory

- Logs/monitoring with Azure Monitor

- Billing with Azure-managed applications and marketplace