This post has been republished via RSS; it originally appeared at: New blog articles in Microsoft Tech Community.

Introduction

SKF, a leading global supplier of bearings, seals and lubrication systems operating 91 manufacturing sites in 28 countries, wanted to transform from a traditional manufacturing organization to a ‘Factory of the Future’ vision. SKF provides reliable rotation to industries all over the world, offering products and services around the rotating shaft including bearings, seals, lubrication management, artificial intelligence and wireless condition monitoring.

SKF has been on a journey to digitally transform the company’s backbone through harnessing the power of technology, interconnecting processes, streamlining operations and delivering industry-leading digital products and services for customers. As part of this transition, they wanted to modernize their factories to transform from a reactive to more predictive workflows using data driven methodology and cloud native operating models in the hybrid cloud environment. Using Azure Arc infrastructure and services, SKF has reduced costs, improved effectiveness, streamlined management and is able to make real-time decisions within the constraints of performance and availability expectations.

In this blog,

A data driven hybrid cloud approach

As SKF looked for a solution that supported their data-driven manufacturing vision for the Factories of the Future, they wanted a solution that was able to support distributed innovation and development, high availability, scalability and ease of deployment. They wanted each of their factories to be able to collect, process, analyze data to make real-time decisions autonomously while being managed centrally. At the same time, they had constraints of data latency, data resiliency and data sovereignty for critical production systems that could not be compromised.

The drivers behind adopting a hybrid cloud model came from factories having to meet customer performance requirements, many of which depend on ability to analyze and synthesize the data. Recently, the Data Analytics paradigms have shifted from Big Data Analysis in the cloud to more Data-Driven Manufacturing at the machine, production line and factory edge. Adopting cloud native operating models but in such capacity where they can execute workloads physically on-premises at their factories turned out to be the right choice for SKF.

The Azure Hybrid Cloud solution offered them a unique value proposition that is aligned with SKF’s Digital Manufacturing vision. It allowed them to reduce implementation and operating costs by using it as standardized IT/OT platform across all factories, with fit for purpose configurations for every factory, while facilitating for distributed innovation and development for competitive advantage.

Azure Arc - platform for digital transformation and application modernization

SKF’s challenge was the need to able to provide over 90 factories with a platform that provides speed, reliability and low cost, while providing support for critical production systems. The platforms and solutions that they wanted to adopt had to be operated both in cloud and on-premises, and ideally be cloud-controlled centrally while enabling a local control point of execution on-premises with elastic scale and high availability using cloud services at the edge.

SKF chose Azure Kubernetes Service on Azure Stack HCI, and Azure Arc-enabled Kubernetes, as the primary hosting platform for modern workloads. The fact that Microsoft has also chosen this strategy, allow them to deploy Azure Arc-enabled data services and Azure Edge/IoT Services virtually on any of their new or existing environments in a consistent automated fashion.

Cloud managed, locally executed services on the edge

SKF has manufacturing plants worldwide that will be automated using their modern cloud-native applications as part of SKF’s Manufacturing Execution System harmonization strategy. Deployed in each manufacturing plant, these applications collect data from machines and sensors in the production lines over to be stored on-premises in the factory location as well as selectively in Azure cloud. This allows for ease of use for applications, analytics, and visualization of data in the factory with low latency and in the cloud for visibility across factories and locations.

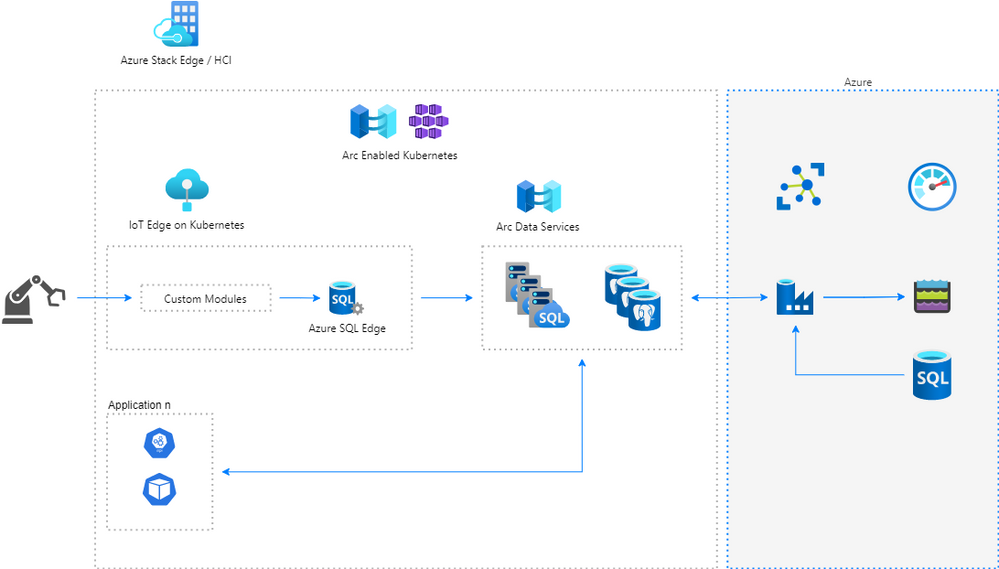

This architecture consists of the following Azure hybrid components:

Azure Stack HCI: Azure Stack Edge or Hyper Converged Infrastructure cluster solutions host virtualized Windows and Linux workloads in a hybrid on-premises environment. Azure Stack Edge and HCI are both running Kubernetes making it easy to manage applications using Open-source tools, such as ArgoCD. This gave SKF the ability to run compute intensive workloads and build intelligence at the edge.

Azure Arc-enabled Kubernetes: Azure Kubernetes Service and Azure Arc for Kubernetes allow ease of operations and control along with cloud connectivity to be centrally managed from Azure. Kubernetes is used as the container infrastructure platform in the Digital Manufacturing architecture. Kubernetes also meets the requirements for scalability and availability for the databases in the architecture.

Azure SQL Edge on Kubernetes: Azure SQL Edge hosts a lightweight SQL database that allows for rapid ingestion, store and forward to the node where applications can make use of time series functions in the architecture.

Azure Arc-enabled data services on Kubernetes: is the foundation for the factory and acts as the central point of data aggregation and persistence. It can be configured to host multiple numbers of either Azure SQL Managed Instances or PostgreSQL Hyperscale. These instances can be scaled up or down dynamically, configured to be high available, always current with the regular updates and monitored centrally in the Azure cloud.

Azure IoT Edge Hub on Kubernetes: Azure IoT Edge Hub enables the data routing on Edge as well as data streaming to the cloud.

This platform makes it easier for SKF to run its business-critical containerized applications in the cloud as well as factory edge.

Declarative infrastructure deployment in hybrid cloud

The ability to automate deployments in a consistent manner across its factories globally was an important factor to SKF to scale out the solution with speed. SKF used Git repository to store declarative infrastructure descriptions and integrated that into their Continuous integration/Continuous deployment (CI/CD) pipelines. ArgoCD, an open-source tool, was used as a GitOps operator for central application deployments to Kubernetes clusters across all factories. Secrets were stored in Azure KeyVault and are retrieved into Kubernetes clusters to operate the applications. Azure portal was used to monitor these applications centrally from the cloud.

This architecture allowed infrastructure management to be fully automated. The application, SQL database or other infrastructure resource updates could be applied with zero downtime to factories.

Low latency data flow from IIoT devices to processing nodes

The factory machines and sensors are connected using a Brown Field Connector (BFC). These connectors collect manufacturing process metrics and sensor data that are streamed in real time to the application platform running on top of either Azure Stack Edge or Azure Stack HCI. The application platform is based on Kubernetes and running for example on Azure Kubernetes Service on HCI (AKS-HCI). Azure IoT Edge Hub and Azure SQL Edge on Kubernetes are used for aggregating the streaming data from all the Industrial IoT (IIoT) devices. This timeseries data containing readings from the machines and sensors is then processed and transformed by Azure Functions and then forwarded to the HCI for storage. The data is stored in a SQL Managed Instance (SQL MI) operated in Azure Arc-enabled data services running in the AKS-HCI. Here, the cloud native applications process the data and drive actions to keep the factories running efficiently.

This architecture not only meets several business and compliance goals by processing data locally on-premises but also gives improved performance due to low data latency. The critical production applications in the factory are deployed in a scalable and high available architecture for Azure Arc-enabled data services using Availability Groups with a cloud connected on-premises Kubernetes. The Azure Arc-enabled data service is a central component in the hybrid architecture and used in every factory as the primary database solution for modern workloads. The data in SQL MI is exposed by a set of APIs running as containers in AKS. Finally, to visualize for example Operational Equipment Efficiency (OEE) they have implemented dashboards to display data real-time on this architecture.

The Dataflow architecture built on top of Kubernetes and Arc gives the capability of managing through a unified control plane as follows:

- Custom OPC-UA configurator module is running on the IoT Edge for Kubernetes that configures the custom OPC-UA data collector module. The custom module reads configurations from the SQL MI database.

- Custom OPC-UA data collector module connects to an OPC-UA server on a Brown Field Connector (BFC) to collect, transform and route signal data from all the endpoints. Data is routed using IoT Edge Hub to other modules like SQL Edge or IoT Hub in Azure cloud.

- Data is stored in Azure SQL Edge enables application to make use of SQL Edge unique time series functions to clean and aggregate the data. It also allows for running machine learning models deployed on top of SQL Edge.

- Data is transferred to Azure Arc-enabled data services where it is stored in SQL MI. Here is where data can be joined with other information which is business critical for the factory. These databases act as the central source of information in the factory applications help drive dashboards and applications.

- Data can further be exchanged and synchronized with Azure cloud using Azure Data Factory to be ingested in either Azure Data Lake or Azure SQL Databases.

Real-time decisions using intelligence at the edge

Business critical applications use the data stored in the SQL MI databases to process and drive manufacturing dashboards for the factory staff to closely monitor the factory operations. Azure Arc-enabled SQL MI running on AKS-HCI delivers low latency high compute performance at the edge to run data analytics workloads that is also highly available. This approach future proofs the platform for adding ML and other data analytics in future. The entire solution is delivered through Microsoft providing better integration, consistency, flexibility at lower cost.

‘Factory of the Future’ is here

As SKF rolls out the solution to its global factories using Azure Hybrid, it is already on path to implement its ‘Factory of the Future’ vision with the benefits of AKS-HCI, Azure Arc-enabled SQL to run their factories at scale. These are some of the most important benefits that SKF has realized using Arc-enabled Data Services.

- Facilitate for distributed innovation and development for competitive advantage

- Reduce implementation and operating costs of their highly available IT/OT platform

- Scale out easily with single pane of glass management and continuous rollout of the latest features and benefits for intelligent edge.

As new Azure Arc services like Azure Arc-enabled ML, Azure Arc-enabled App services, SKF has future proofed their factories using the Azure Arc and Azure Hybrid Cloud services.

Conclusion

SKF is a visionary manufacturer who is rapidly adopting cloud to transform the business using data driven methodology and cloud native operating models in a hybrid cloud environment. Azure Hybrid platform with Azure Arc-enabled data services, SQL MI, AKS-HCI on Azure Stack HCI and Azure SQL Edge with Azure IoT hub have been the cornerstone of this transformation. It has been possible to get this alignment due to a productive partnership between two global leaders – SKF and Microsoft to deliver industry-leading digital products and services to customers.

To know more about Azure Arc, Azure Hybrid and SKF's journey please sign up to watch the Azure Hybrid and Multicloud Digital Event.