This post has been republished via RSS; it originally appeared at: New blog articles in Microsoft Community Hub.

In a game-changer for the energy industry, actors including vendors, grid operators, and digital solution providers are joining forces to pilot digital twin solutions that can help accelerate the energy transition. Data from the grid is often inaccessible, lacks context, and is isolated in siloed systems. For Distribution System Operators (DSOs), a digital representation of a physical grid system unlocks the ability to make data available and leverage it for increased energy efficiency and early risk mitigation.

With the addition of Internet of Things (IoT) devices, information such as sensor readings, status updates, and performance metrics can be integrated into the digital twin for an even more detailed and accurate view of the power grid. In essence, bringing IoT data into the digital twin enables vendors to operate closer to actual load flow limits by placing relevant data in the context of ongoing operations. It also offers the opportunity to build out features in the digital twin like load flow visualization and analysis, load and production forecasts, and topology and grid alterations. Digital twins are making smart grids a reality!

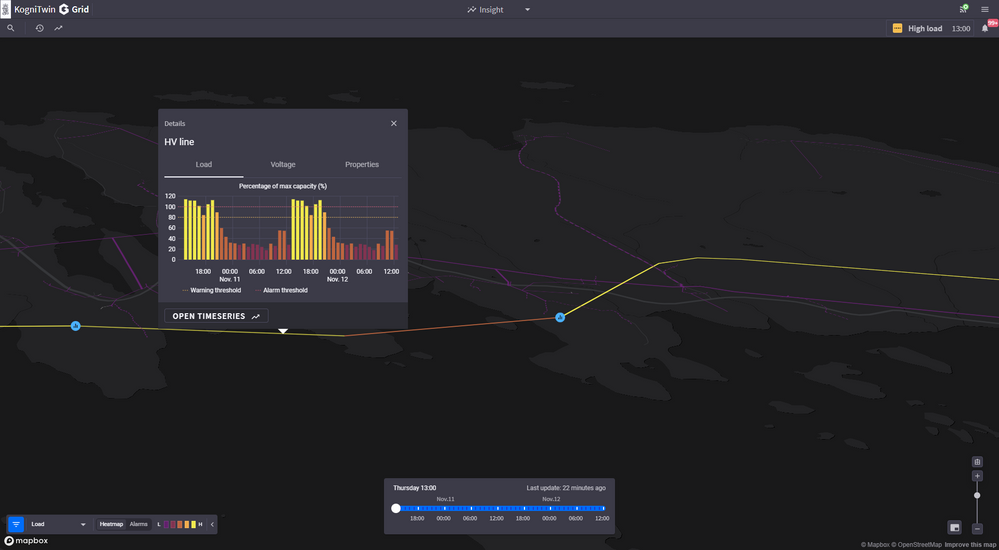

Shown here: Kognitwin® Grid digital twin interface showing simulated maximum capacity parameters for an overhead line where a sensor is installed. The blue dots represent a Heimdall Power sensor, called a Neuron, while the bright yellow line shows an overhead power line that is nearing or already over the max load capacity. The right-hand image shows the current simulated load flow in the line, and the estimated load flow for the next 48 hours using static line ratings. The next step for the research initiative will be to have the simulations consider the dynamic line rating as measured by Heimdall Power’s Neuron.

How it works

A digital twin that is agnostic and uses CIM (Common Information Model) standards helps ensure that information is in the correct format and easy to exchange across applications. Supported data formats include NIS/GIS for data about physical assets that are connected and part of the power grid, ADMS data for switch changes, SCADA for visualizing sensor data, and AMI-data to analyze historical values and create forecasts. Data is sourced from the appropriate operators and vendors and information like switch states, load- and production forecasts, and grid model data is collected so that a digital twin of the distribution power grid can be created.

The data from a vendor’s system is transferred to the Microsoft Azure Cloud using REST APIs. Vital information from sensors is transferred to a timeseries Managed Microsoft Database Service (Azure Postgresql and TimescaleDB - which is an extension that gives Postgresql time-series capabilities) and then ingested by the digital twin as time-series data so that the captured information can be displayed in a visual map-based application. A digital twin solution can place collected data in the context of the whole grid system, offering an interactive way for users to access information like:

- Nominal voltage

- Load heatmaps

- Warnings and alarms

- Topology

- Simulation information for the following 48 hours

- Potential grid bottlenecks

- Voltage deviations

- Grid congestions

The best part is that implementation is uncomplicated. For DSOs, access to historical data is the only requirement. Additional data collected from IoT devices like vendor-supplied equipment is similarly transferred to a Microsoft Azure Cloud tenant, and APIs for data transfer are built and hosted on Microsoft Azure to give users and partners instant and secure access to their data. Once this data is sourced from the appropriate operators and vendors, the necessary switch states, load- and production forecasts, and connectivity grid model can be used to create a digital twin of the distribution power grid.

Customer use case: systems integration

In one customer use case, the Norwegian DSO Tensio and the software vendor Kongsberg Digital utilized a digital twin solution to make data from Heimdall Power’s overhead line sensors available directly in the twin so that the DSO could get an overview of what is happening in the grid. Having vendors like Kongsberg Digital and Heimdall Power cooperate to remove data silos between systems offers true data liberation, with minimal effort or investments of time and resources from the DSO’s side.

Sensors give a snapshot of power line conditions. By combining IoT data from a sensor with data in a grid model, operators can get a more complete picture of the entire system.

IoT devices such as sensors can collect highly accurate and detailed data about the physical state and performance of the grid. In this use case, intelligent multi-sensors from Heimdall Power were applied to measure a wide range of overhead power line parameters and provide Dynamic Line Rating (DLR), capacity forecasting, ice monitoring, and vibration analysis. Armed with this information, grid operators can better understand line capacity potential for individual overhead lines, operate closer to actual capacity limits, and utilize existing grid infrastructure more efficiently.

Shown here: The IoT device, Heimdall Power’s Neuron, attached to an overhead line

Image source: Heimdall Power - We are digitizing the electric grid

Although it’s difficult to measure efficiency gains considering the many components involved in estimating line capacity, ongoing data collection from research initiatives suggests an impressive increased line capacity of up to 25%. The theoretical increase of the overhead power line capacity is even higher at times, although at the moment limited by other components in the configuration. Heimdall Power has more than 200 sensors installed in different power grids around the world. So far, the installed sensors show 33% or more increased capacity over 50 % of the time. For grid operators, this means that grid flexibility can be leveraged to mitigate grid congestion, meet customer electrification demands, and work towards optimizations like minimizing the Cost of Energy Not Supplied (CENS). This example illustrates how smart grids become a reality when good quality data, integrated IoT sensors, and a cutting-edge digital twin solution are brought together.

Digitally transforming the way things work today

The successful integration of data from various systems (in this case a digital twin and an IoT sensor device) is a huge win for interoperability and industry collaboration, showing how data can be aggregated and relationships established to create useful insights in the form of models, graphs, and more. IoT sensors can collect vast amounts of data. By allowing users to set parameters and thus view only data relevant to grid capacity in a visual interface with simulation capabilities, a heightened level of interoperability is unlocked so that grid operators can make more informed decisions and get the most out of every overhead line.

What’s next? Since IoT data has been successfully brought into a digital twin for grids, the next step could be using Dynamic Line Rating (DLR) data from the sensors to power advanced simulations of grid bottlenecks in the digital twin. This would elevate the value of vendor partnerships for DSOs, giving them confidence that results in the digital twin are based on actual measured data and reflective of near real-time operating scenarios.

It’s still early days for the digitalization of the energy industry, but this use case shows the extreme impact that vendors and operators can have when they go digital with a digital twin. The market might not be up to speed yet, but Microsoft’s Marketplace is. Find Kognitwin® Grid there to see how you can handle the grid challenges of tomorrow and achieve smarter, safer, and greener grid operations.

Kognitwin® Grid

Kognitwin® Grid is a sophisticated SaaS solution that offers grid insights through capabilities like visualization, topology processing, and forecasting simulations to show near real-time, modeled, and predicted states of the power grid. With just the click of a mouse, users can access this information through a map-based application or through APIs. It gives you the right data in the right context, presented in a user-friendly interface that reduces complexity and offers new ways of working. Kognitwin® Grid provides a full load flow analysis of the entire grid model across all voltage levels and predicts load flow and voltage deviations for the next 48 hours. Increased grid utilization, optimized investments, improved reliability – it’s everything a smart grid needs. Check it out on the Azure Marketplace: All products – Microsoft Azure Marketplace

Heimdall Power Neuron

Heimdall Power’s Neuron is a self-powered multisensor mounted directly on the power line. The Neuron conducts a variety of measurements which are transmitted periodically using LTE-M (CAT M1), NB-IoT or LoRa communication to Heimdall Power services hosted by Microsoft Azure. The intelligent IoT sensors work in tandem with our software Heimdall Cloud – powered by machine learning, weather data and advanced modelling – to bring grid companies powerful, real-time insights on the status of your power lines. Insights about Dynamic line rating, line sag, capacity forecast, line vibrations and ice load can be viewed in Heimdall Cloud or easily integrated to other systems like SCADA and digital twins through APIs. Heimdall Power helps digitize the power line enabling more optimal utilization of existing grid infrastructure. Soon available on the Azure Marketplace.